The Inspector Calls – those words will strike fear into any business owner when Governmental Inspectors are concerned. Imagine then you owned a gunpowder factory back in the day and all the possible hazards that may exist and the fines for any that are found. Not a visit to look forward to…

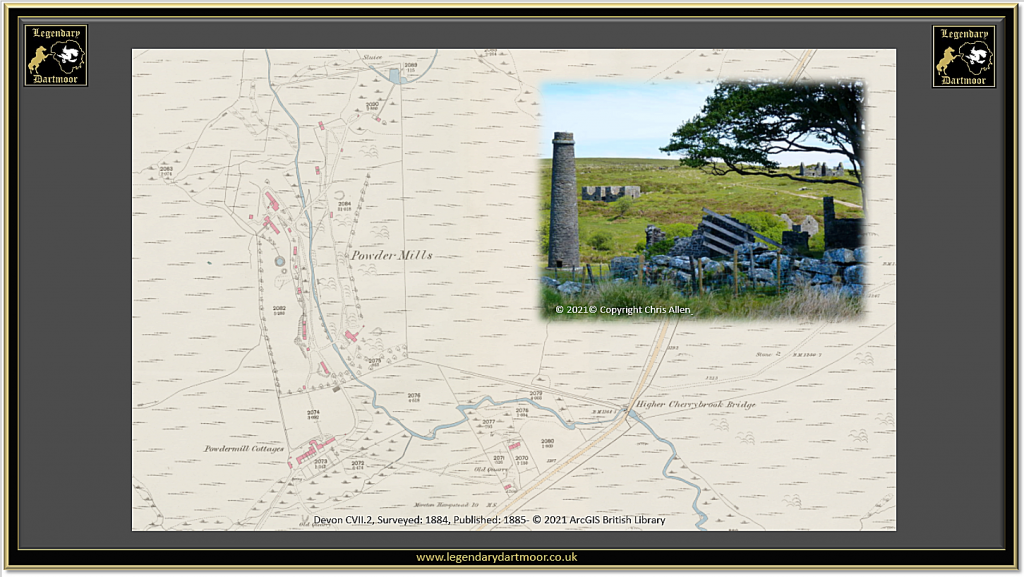

In 1846 Mr. Frean began producing gunpowder at his factory at Cherrybrook. But why a gunpowder factory in the middle of Dartmoor? One of the answers for this can be found a few miles up the road at the Birch tor mining complex, this and dozens like it all needed gunpowder or ‘blackpowder‘ as it was called for blasting the lode bearing rocks of the mines. In addition there were various quarries who also needed blackpowder for blasting rock such as Swell tor, Foggintor and Merrivale. During the 18th and early 19th centuries farmers were also using gunpowder to clear rocks from lands that were being enclosed, evidence of which can be seen by the ‘clearance cairns’ at the edges of the newtakes. So in terms of a viable market, this could be found locally and the blackpowder was in great demand. Needless to say the possibilities of accidental explosions was ever present and so the powder works would regularly be inspected by a governmental official to minimise the risks. In the late 1880’s Captain Vivian Majendie R.A was one of Her Majesty’s Inspectors of Gunpowder Works who visited Frean’s Powder Mill for an inspection which ended up in a court summons. He was charged with keeping in the corning and granulated house 4,100 lbs. of gunpowder to be ‘corned’ which was 1,412lbs. above what the law stated was allowed to be stored at any one time. He was also charged with on the same date keeping 4,180lbs. of gunpowder in the press house, again 1,940 lbs. in excess. The final charge was for willfully neglecting and delaying to remove with due diligence a large quantity of finished gunpowder weighing 25,000 lbs. from the packing room to the store. Frean pleaded guilty on all charges. the prosecution pointed out that in theory the fines should be fined 2s. per pound and the forfeiture of the excess powder in the first two charges and the same for the third but in addition £5 a day for which the offence continued. In the end the Bench decided a penalty of 2d per lb. on the excess powder and £5 for the third offence plus costs.

To illustrate the importance of these inspections in maintaining a safe working environment the outcome of an explosion could be disastrous and expensive. In 1851 there was a tragic incident at Powder Mills when; “One of the houses at the Dartmoor Powder Works took fire last week. One man was so much burnt that he died shortly after the accident; three other were also much injured, but they are doing well. The man who received the fatal injury has left a wife and five children. The next morning another part of the works was blown to atoms by an explosion.” Bell’s Weekly Messenger, July 19th, 1851. In the November of 1857 another explosion at Powder Mills severely injured two man. Following this in the December of 1857 a further two men, named Dodd and Hamlyn were killed in an explosion at the works, the damage was estimated at £500.

Again in the July of 1884 Captain Majendie returned to Powder Mills for another inspection this time as H. M. Inspector of Explosives. His findings resulted in charges being brought at a five hour hearing at Tavistock Court. This time it was the new owner Mr. Charles F. Williams who was being charged with fifteen separate breaches of the Explosive Act of 1875. These were initially sent in a report to Williams was itemised as follows:-

1) Having a glazing house not properly lined and constructed.

2) Packing House -The floorboards are open at the joints in several instances, particularly near one of the doors, and between these joints earth and dirt and accumulated powder are visible and can be easily extracted; one open joint was three-quarters of an inch wide, and actually in one place blades of grass were spreading between the boards. The wood lining was very defective. This in some place does not come down to the floor, and grit from behind is easily shaken down; and at one of the windows it is shrunk away from the wall, and there is a wide, open space below the window-sill, which space is full of dirt, cobwebs &c. One of the door grates over the floor, is hung on iron hinges which are only partially covered with canvas. Part of the hooks of the scale and beam of uncovered iron are exposed. A door at one end opens into an unlined and non-clean ante-chamber in which were some barrels put back for repairs. There is no floorboard and division between the two rooms, the door is only latched, and since, and since it does not fit closely, grit from the ante-chamber may easily be conveyed into the packing house proper.

3) Sizing House – the general standard of cleanliness in this building was far below what is now usually observed in other factories.

4) Glazing House – A portion of the lining at the back is so open as to expose over 1 inch width of bare plaster. There is a hole in the floor, some putty from a number of iron nails is off, exposing the iron. The sweeping of the building had been very imperfectly performed, and no sufficient attempt had been made to search out places where dust and dirt might accumulate. Such accumulation in one place in particular was considerable. The glaze tubes had large masses of iron unnecessarily exposed.

5) Glazing House 2 – The lining in one corner had slipped off or rotted away for a width of nearly three inches, and in places such more exposes the bare masonry from which grit was detached had mingled with the powder. All the portion of the wall near the driving gear, for a height of at least one foot from the floor, was uncovered, and grit therefrom had mingled with the powder There were holes in the floor, and also an open joint near the door. There were several exposed iron nails, some from which the putty had come off, and one which had never been puttied at all.

6) Corning and Dusting House – the wood lining fits so ill that on the right end of the house there is a bare space of masonry about three or four inches wide. Behind the gear on the same side there are large areas of uncovered masonry on the gritty surface of which the powder lay thickly. Knots has fallen out of the lining, leaving further further openings of the bare masonry. The sweeping had been exceedingly imperfectly performed and there were considerable and unnecessary accumulations of powder dust in place. There were several holes in the floor. A lining board behind the door was loose and further masonry was thus exposed. There was a hole in the floor. The lining near the machinery was incomplete.

7) Charge House – The floor planking in the centre was loose, and powder was lying thickly on the earth and among the grit below. The lining which partitions off an unused and unlined part is carried up to the roof. The house is excessively dirty, the roof, angles of the walls, and behind the door being festooned with cobweb and dirt accumulations.

8) Mixing House – The whole of the lower part of the lining at the back of the house and portions of planks at other parts are loose, leaving chasms for powder and dirt to get to bare masonry. Also grit falls from behind the lining onto the floor. There was a large piece of exposed iron behind the door. The house in one place in particular was very dirty, and insufficiently swept. The saltpetre bin bin projects into an unlined room, and is under the unlined slate roof.

9) Changing House – The fender is quite unsuitable and insufficient for the protection of the men.

10) Stove – The interior or stove proper has, I observed, a bare slate floor, from which (mingled with the powder) it was easy to pick up detached particles of slate and grit. There was a hole in the floor of the ante-chamber.

11) Express Magazine – The floor of this building is very imperfect.

12) Factory Magazine – The lining it is so ill as to leave gaps at the junction of the floor. The floor is so very imperfect and ill-laid, and many openings in it. Barrows for removal of powder are open barrows, and not such uncovered barrows or vehicles as by section 10 are required to be employed.

Special rule as to the removal of powder coruscations. This rule is affixed in the various buildings, but I cannot find that it has been formally approved. The general appearance of the buildings is unsatisfactory in the extreme. They are dingy and comparatively uncared for, and the whole factory, to express myself plainly, has a starved and careless appearance. I consider that it has distinctly gone backwards rather than advanced, and I am not prepared to take the responsibility of allowing such a state of things and a long list of defects such as I have enumerated above to continue. It is my intention to lay the matter before the Secretary of State with a view to proceedings being instituted against you for such of the offences as may be advised. But I shall be willing to postpone doing so for a period not exceeding seven days to afford you an opportunity of offering such observations (if any) as you may desire.” – The Tavistock Gazette, July 4th, 1884.

Mr. Williams then replied to the report basically saying he found it personally offensive and was prepared to meet Captain Majendie at the mine to discuss his findings at the works thus being able to voice his objections to the report. At the hearing Majendie gave his evidence most of which pertained to his report and he was the only witness for the prosecution. Several witnesses were the hear for the defence amongst whom were several workers from the factory. In a nut shell they denied the findings saying the place had been properly swept and Majendie was mistaken about finding cobwebs everywhere. It was also intimated that the ‘unreasonable’ findings of the inspection where the result of Williams’ terse reply and that the guilty party should be Majendie for negligence in his work. In the end the prosecution withdrew seven of the charges and so the Bench retired to consider the remaining eight. When they returned the verdicts were the dismissal of the charge concerning the Charge house. For the remaining seven they found the defendant guilty and fined him £2 on each charge and £6 6s. costs, a total of £14. It was pointed out that if all fifteen charges had been proven the fine would have been £150. Interestingly one point the defence made was that there had never been an explosion at the works. This was a bit of poetical licence and should have said whilst under Williams’ ownership. D. Campbell in his book Powdermills, p. 89. states how later that year there was an explosion at Powder Mills and luckily there were no workmen on site at the time.

One of the greatest dangers at a gunpowder factory would be that of a spark setting off an explosion caused by exposed ironwork and accumulations of the floor, hence the concerns with exposed iron, dust, grit and powder not being swept up and poorly lined floor and walls. As to cobwebs, Majendie considered these were a useful clue to an inspector as to the lack of housekeeping

Legendary Dartmoor The many aspects past and present of Dartmoor

Legendary Dartmoor The many aspects past and present of Dartmoor