For centuries British leather tanners used oak bark to tan skins and hides in order to make them waterproof and durable. This was a process whereby the bark is stripped from trees during the spring and summer seasons. Then it’s dried out for a couple of years and ground down and kept in the bark store until needed. The next stage is when the tan is soaked out of the bark using a cold water wash and when considered to be strong enough it’s pumped up to the tan yard for the process of tanning the leather to begin. It was said that the average size tannery would get through around a ton of oak bark each week.

But how did the oak bark get to the tannery in the first place? Please greet the ‘rippers,’ these were men, women and in some cases children whose job it was to strip the bark from oak trees, heap it up, let it dry and take it to the tanneries or bark store. Here is a description of the process written in 1853 – “The woods of “Fair Devonia” are now ringing with the sounds of the woodman’s axe and the songs of the “rippers” mingled with those of the thrush, linnet and blackbird. The three weeks or month of the ripping season is always a merry time for the agricultural worker as he receives better pay… The barking season this year has been most favourable to the operation of the ripper, as he has had almost sunshine with but a few showers. The time chosen for their work is when the sap is between the stock and the bark, before the tree has put forth its foliage, as then the quality of the bark would be deteriorated, and rendered almost useless for tanning purposes. In extensive woodlands such as around Bridford the woodsman goes around and marks the trees for destruction. The woodsman, or a dozen men, speedily follow and cut down the saplings or smaller trees with the axe. It is only on the larger ones the saw is at all used, as it prevents the “stumps” from growing again. The “rippers” follow with a short iron instrument, which is inserted between the tree and the bark, speedily stripping it, the hands being carefully protected with leather, as it is no easy work. Boys pick up the scattered bark and carry it to women to be piled in heaps for the suns rays to dry, and in a fortnight or three weeks it is ready for delivery to the tannery.” Basically the “short iron instrument” noted above was locally known as a ripper iron or barking iron which consisted of a rod about two feet long, with a handle at one end and a point shaped like the ace of spades at the other. This would be used to remove the bark in pieces about two feet long and as wide as the circumference of the tree permitted. The dead outer bark and lichen was then scraped away and the bark strips were propped up to dry. It was said that oak bark when ‘ripped’ in the spring was four times as effective as a tanning agent than that gathered later in the year.

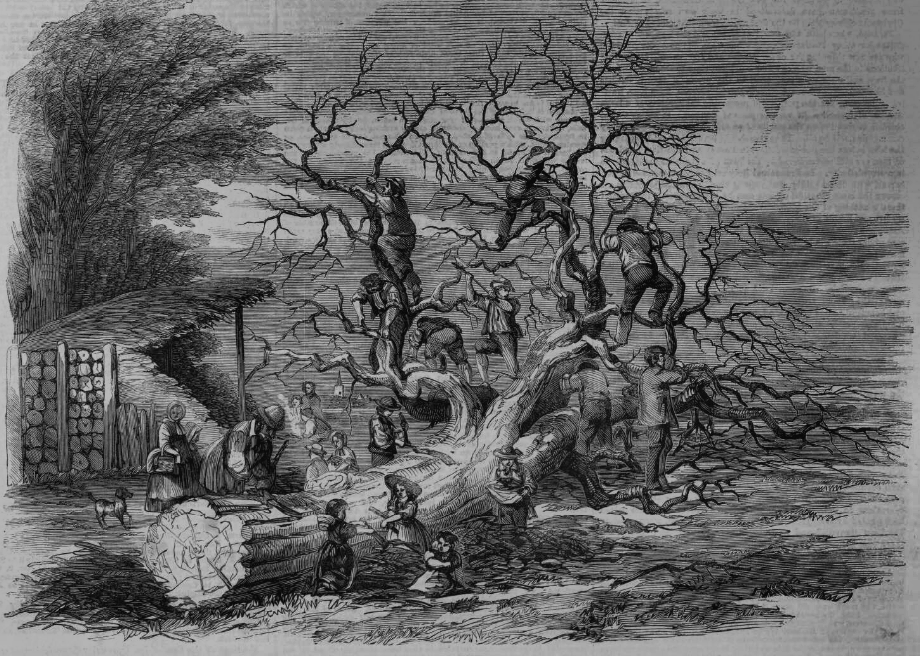

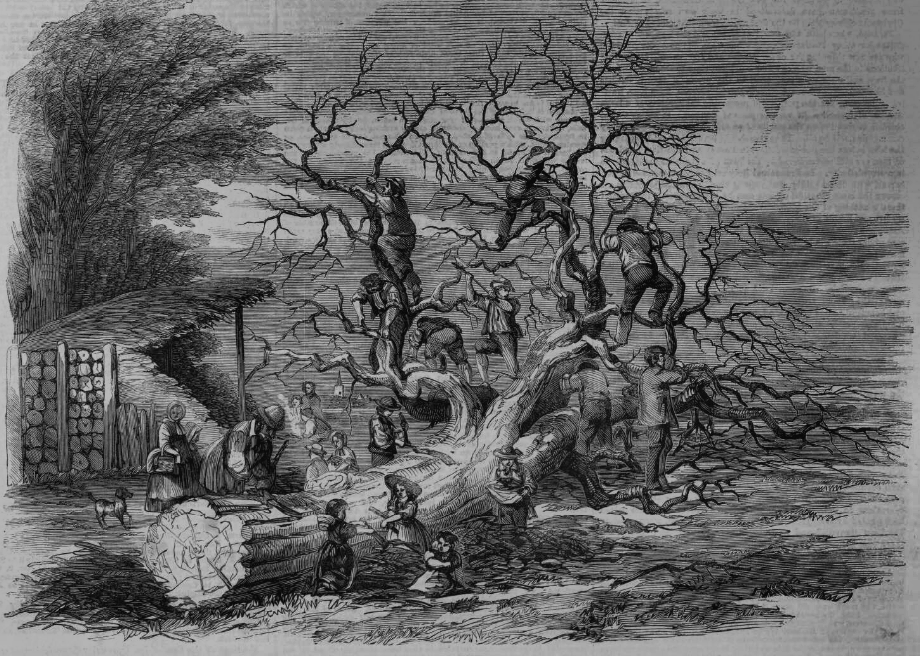

Another description of a ‘barking’ scene comes from 1859; “It is a busy scene, this oak-barking, and one in which young and old – man, woman and child – can be actors. While the young and active men swarm into the branches, and take up perilous positions aloft, the old men, and even the women can be thumping away below, loosening (with the back of an axe head) the bark of detached branches, or of those arms near the tree which have been brought near the ground; while the children can find ample employment in the same occupation, or in piling into heaps the detached pieces of bark.. When there is a good staff of workers, who can industriously ply their barking-irons and peeling irons, or their axe heads, it is astonishing to see with what rapidity a gnarled and rugged tree can be converted into a sleek and shining specimen, that looks something between satinwood and ivory. By dint of a little judicious thumping the rough exterior is quickly exchanged for the polished surface – from which an instructive moral may be drawn by those who teach the ingenious arts and the young ideas – and the peeling iron is made to do its work with great efficiency, as well as rapidity. Only the chief branches and arms of the tree are left for this purpose; all the lesser branches and twigs are bound up into “cords,” with the other loppings and chips, which are to the woodsman what dripping and fat are to the cook – his perquisites.

Oak barking always makes a pretty scene. The number and variety of the figures, and their diversities of attire and posture, afford good material for the artist and amusement of the spectator. The tortuous branches of the felled tree are, here and there, brown with the yet unremoved bark, and, in other places, gleam white against the blue April sky.” – The Illustrated London News, April 16th, 1859.

Many of the Devonshire newspapers would carry adverts for bark rippers around April time for various woodlands around the county. The ‘ripper gangs’ could consist of anything from a handful to fifty plus depending on the size of the wood. One large wood in 1817 employed 4 carpenters, 8 labourers, 37 rippers (0f whom 28 were woman and girls and 8 were boys) and 2 draught horses. The daily wages for the carpenters were 2 shillings a day, the labourers between 1 shilling and 8 pence and 2 shillings and 6 pence, adult rippers earned 1 shilling and 6 pence for the children. In 1937 the daily rate for a ripper had risen to two shillings a day. As with any seasonal work that was short lived and labour intensive welcomed wages were earned and in many cases the whole family would take advantage of it. As can be seen above Oak ripping was no exception and there are numerous cases of parents being summonsed for not allowing their children to attend school as they were needed in the woods with the bark harvest. It was not only for non-attendance at school that rippers could find themselves infront of the Bench. It was not unheard of for some of the men to be tempted to poach a free meal from the rabbits and other such woodland delicacies which abounded. Some would innocently take their lurcher dogs to work with them, just to give them some fresh air and exercise?

On hot days the strenuous work could easily work up a terrific thirst and so it was not uncommon for the rippers to be supplied with large quantities of beer or cider. So common was this practice that one Devonshire brewery in 1852 placed the following advert in the local papers; “TO CONTRACTORS AND PERSONS ENGAGED IN BARK RIPPING – J. K. begs to intimate that he is prepared to supply them with any quantities of his EIGHTPENNY BEER which will be found admirably adapted to the use of Bark Rippers and Agricultural Labourers, and incomparable better drink for persons engaged in field work or any laborious occupation, to the best cider, at the same price – sold in casks of 4½, 9, 18 and 36 gallons.”

At the beginning of the 1800s many oak bark dealers were complaining that there was something of a cartel formed by the tanners who at the beginning of the ripping season fixed the buying price of bark to suit at what was deemed as ridiculously low prices. In effect this meant that the true price of bark was never realised until the tanners had filled their bark stores for the year thus allowing the dealers to raise their prices for other purposes. In some cases tanners would also purchase their own oak timber which meant less trees available for the timber and bark dealers which again affected the price of bark.

In the early 1830s the average price for a ton of bark was five pounds and ten shillings a ton but by 1835 the price had dropped by ten shillings due the the import duty on foreign bark being lowered. Come the 1860 the price had risen back up with maiden bark fetching around six to seven pounds a ton and coppice bark three pound a ton. The price of the bark was solely dependent on the demand for leather hence the fluctuation. During the Napoleonic wars the demand was high so the price rose rapidly but then dropped back to more sober levels. Naturally when the bark prices were high it would be a vary tempting thing to steal. At the Devon Midsummer Sessions of 1857 one John Lamacraft, a labourer from Moretonhampstead was charged with stealing two hundred pounds of oak bark, the property of Robert Thomas, 200 lbs from William Ellis, 200 lbs from Nathaniel Berry and another 200 lbs from Nicholas Adams. He was sentenced to four month imprisonment with hard labour.

By the late 1800s/early 1900s many country estates and bark agents were reporting that it had become difficult to dispose of the oak bark. To some large estates this meant a loss of revenue which could have amounted to around £1,000 a year. The reason for this rapid decline was twofold, firstly foreign leather manufacturers were importing raw English hides and treating them with artificial and cheaper chemical tanning materials then exporting their leather back to England to be sold much cheaper than the traditionally tanned leather. Although products made from this foreign leather were far inferior the demand for them rapidly increased. Secondly, this then meant that the traditional leather makers could no longer compete with the cheap exports which resulted in many of the tanyards closing down – hence the fall in demand for oak bark. Today J. & F. J. Baker of Colyton, Devon, claim to be the last traditional oak bark tanners in Britain.

A Ripper Gang from 1864

It goes without saying that working with saws, axes, and ripper irons were if one was not careful a recipe for disaster and often rippers would be losing fingers, severe cuts and ultimately loss of life Another of the dangers faced by the rippers was a sudden thunderstorm, clearly with lightening flashing around the last place one wanted to be was in a woodland along with a host of metal tools. In the May of 1845 a terrific thunderstorm crashed across the Moretonhampstead area and; “In the wood in this parish, where workmen were engaged in ripping the bark from the coppice wood, the hail and rain came down in torrents – the lightening at the same time came down in sheets, and most vivid, while the thunder rolled awfully overhead. It was an awfully grand and terrific scene, the lightening frequently striking on and playing over the surface of “the ripper” an iron tool used by these workmen in separating the bark from the wood. In fact, such at length was the effect of this, that fearing for their safety, and becoming affrighted, the men in a hurried manor left their work.” – The Exeter Flying Post, May 29th, 1845.

Another danger was that of fire especially when it occurred in the oak bark shed or ricks as was witnessed at Buckfastleigh on two occasions. In the January of 1882 a huge fire broke out at the Buckfastleigh tanyard belonging to the Hamlyn Brothers. At the time there were four huge ricks of oak bark which caught fire. Each rick was comprised of between 200 and 250 tons of the best quality bark valued at around £5 at ton. Unfortunately there was a strong breeze which had the effect of blowing smouldering chunks of bark around the site. On three occasions a fire were started in the nearby woollen factory by the wind-blown embers but fortunately were quickly extinguished before much damage was done. It took two days to bring the fire under control although the ricks continued to smoulder for a few more. It was estimated that the cost to the Hamlyn Brothers’ was between £6,000 to £7,000 pounds. This included the loss of the bark, the damage to the bark mill and the amount of time it was out of action due to the loss of bark. It was thought the cause of the fire were some young boys playing with fire who were seen coming from the western rick just prior to the fire As if these problems were not enough in the June of 1895 0nce again the bark mill at Buckfastleigh belonging to the Messrs. Hamlyn Brothers caught fire. Several local fire engines were soon at the scene and managed to remove a lot of the bark before getting the blaze under control, unfortunately the building was destroyed.

Some other uses for oak bark were glue making whereby when the bark extract was mixed with glycerine and a normal glue it this was used for fixing leather to iron. In Victorian times there was a wonder cure for sore throats called ‘Pepper’s Tannin Throat Gargle’ which was a concoction of tannin extract from oak bark and oak galls mixed with glycerine Numerous adverts appeared for this product which claimed it was useful; “as a mouthwash in cases of disagreeable breath arising from bad teeth, disordered stomach, mouth ulcerations, or other causes, especially when attendant on a cold. As a cure for ordinary sore throat, with its painful and sometimes dangerous symptoms, the Tannin Gargle is far better than anything of its kind.” The cost of this wonder product in 1884 was one shilling and sixpence a bottle.

Sometimes when a harness or yoke bows were wrongly fitted to a workhorse it could cause hard painful skin sores AKA ‘galls’. At the first sign of such it was suggested to; “bathe those parts before they are ‘galled’ with cold water until the outside skin appears quite soft and then bathe those parts with a strong decoction of white oak bark. Let this be everyday and the skin will soon become much harder and tougher than it usually is.”

An old cure for chilblains was to take 10 pounds of oak bark, put it in a large kettle and add six quarts of water and boil it down to four quarts, then simply soak the feet in it. A similar treatment was said to cure Foot and Mouth Disease whereby a handful of Blue Vitriol was added to every two quarts. When cooled and dissolved this would then be used to bathe the hooves with the solution three times a day. In a similar light, to help stop diarrhoea in sheep a potion of oak bark boiled in water would be given to them.

At one time when fishing nets were made from hemp they needed to be ‘Barked’. This was a process whereby oak bark would be cut into strips and boiled in a copper filled with water for several hours. Once the tannic acid had been dissolved out the nets would then be soaked in it which stopped them rotting when in sea water. Staying with the fishermen it was a tradition that the Brixham trawlermen always dyed their sails red-brown at the bark yards. Each smack owner would have his own preferred shade of colour and each bark yard had its own secret formula for making the dye. Amongst the ingredients were quantities of oak bark, tallow and water which were boiled up in large copper vat, the sails would then be placed in the vat and stirred with a large wooden paddle until ready. The bark yard owners would only supply the dye and the copper vat the stirring of the sail was done by the crew of the smack. A similar process was recommended in order to preserve hessian corn sacks from rotting on farms. This time it needed 2 lbs of bark to every 17 – 18 pints of boiling water into which the sacks soaked for 24 hours, washed in clean water and set to dry.

In the days of the leather football the finest of these were always made from oak bark tanned leather as it made them waterproof and keep their shape. One such make of ball was the ‘Victor’ which was advertised and sold by C. Limpenny of Plymouth. Who stated that one ‘Victor’ ball was used in 24 matches played by Bolton Wanderers Who remembers the sting of getting such a ball on the leg or even worse in the face?

An unscrupulous use of oak bark in the early 1800s was to ‘doctor’ cheap wine by adding oak bark, alum, water and other astringents to give the flavour of good wine and adding logwood and alkanet root to give the colour.

At one time the use of copper sulphate was used for pickling seed wheat which was intended to destroy the diseased grain that caused ‘smut’. Some nefarious manufacturers began combining the copper sulphate with iron sulphate which was much cheaper although useless for the pickling process. One way for a farmer to tell whether or not his copper sulphate was the genuine article would be to add a solution of oak bark to a small sample, if it turned black then it had been adulterated.

Woodlands can be mystical places and the following tale relates a truly mystifying experience of one ripper – A gang of rippers were just finishing their days work when one of them realised that he had left his ripping iron behind and so went back to fetch it. As he stooped down to pick it up a strange sensation came over him and was unable to stand back up. Then he heard the sound of high-pitched laughter coming from all around him, immediately he realised he was being Piskie-Led and so tried to turn his coat inside out – the tried and tested way of stopping the piskies curse. Sadly he was unable to do this and began to stumble aimlessly around the wood. Several hours later and having not returned home his wife went out in search of him when she came across one of the ripper’s fellow workmen and asked him if he knew where her husband was. Rather puzzled he replied no and stated the last time he had seen her husband was when they left work that evening. By this time she was becoming concerned and went to the place in the wood where he was last seen. Eventually she came across the poor soul, soaking wet and gibbering incoherently about being Piskie-Led. Once he came to his senses he related how for hours he had been held under the spell and when it was finally lifted he could barely crawl along and was completely lost. He then stumbled into a stream and had just clambered out when she found him. Now his good lady was quite a level-headed woman and there was no way she was falling for that story. Nonetheless the ripper was convinced he had been Piskie-Led because he knew only too well that old Zak Toogood had also fallen victim to the little folk in the same wood. Was this a true case of being Piskie-Led or had the ripper over indulged in the “Eight Penny Beer’ that was “admirably adapted to the use of Bark Rippers,”?

Legendary Dartmoor The many aspects past and present of Dartmoor

Legendary Dartmoor The many aspects past and present of Dartmoor